Electronic Design

Most of our projects are based on our electronic designs.

Our designs are either from scratch or from existing designs, re-engineered to

take advantage of the latest technology.

Working from requirements, our designs focus on issues that most benefit the manufacture and life of the product.

Design considerations include:

- Component count, cost and availability

- Ease of manufacture and configuration

- Power supply range, stability and efficiency

- Environmental suitability and tolerance

- Flexibility for future requirement changes

If you own the rights to an existing product and don't have the supporting documentation, we may be able to

reproduce the same or equivalent design to re-manufacture the product. Most re-engineered products can benefit

from improvements to reduce cost and power requirements etc.

A low power data logger with satellite interface.

A first prototype from schematic diagram to prove design.

Designs may be prototyped before printed circuit cards are made.

Circuit card and housing design

Electronic circuits are captured as schematic with a software package. The capture package

produces net lists, which combined with footprints of all the components used, are

then used to lay out circuit cards.

Factors that govern the layout of circuits include:

- Minimisation of card area to reduce cost

- EMC considerations, in extreme cases, with lightning suppression

- Ease of assembly by pick and place assembly plant

- Clearance of mounted component in final assembly

- Minimisation or if possible, elimination of wiring

It is usual to lay out a circuit card in conjunction with the design of the product

housing. We have solid modelling facilities that are used in conjunction with

the design of the circuit cards to prove the design before commissioning circuit cards.

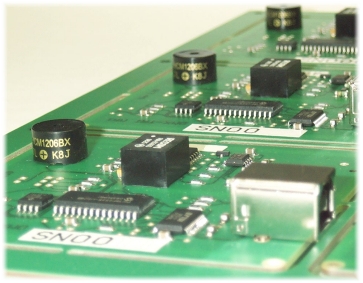

Surface mount isolated interface cards.

Prototype PCBs are laid out from schematics.

Prototypes may be used to test and demonstrate firmware.

Firmware Development

Specialising in real time and multitasking software for microcontrollers, our developments range from intelligent

ballistic motor control, through protocol interfacing, data acquisition and logging, to bingo calling machines.

The majority of our developments are realised for the Microchip and Atmel ranges of microcontrollers.

Designs are predominantly developed using object based techniques and documented before implementation.

Elements of previous designs include:

- Telemetry transducer interfacing

- PWM closed loop power control

- Proportional valve control

- Protocol stack management

- Satellite link management

- Battery state monitoring

Although our core business is based on firmware development, we also develop API's, drivers and some Windows

applications.

Programming languages we use include:

- Assembler

- C, C++

- Ada

- VB, VBA

- HTML, PHP, Java

Software development of DC motor position servo.

Documentation is produced first to define system operation.

Software objects and messages are developed from diagrams.